The LIFTEX Process

| 100% Safety | No “Swiss Cheese” Slabs: | Not An On-The-Job Training Exercise | Fully Occupied Lifts |

|---|---|---|---|

| Methods have been attempted which separate the roof from its support structure, then fight wind and gravity with guy wires and building blocks. Only LIFTEX keeps the structure intact, thereby maintaining and even improving stability and integrity throughout the entire process. | Any lifting method dependent on guy wires needs an array of anchor bolts, leaving “swiss cheese” holes in the floor slab. Only LIFTEX uses the building’s existing structure, maintaining stability and avoiding floor damage. | LIFTEX work crews are experienced roof-raising experts. They fabricate the steel in-house, deliver and install it, accomplish the lift, and enclose the new height. Most crew members have been performing this work for over 10 years. We don’t license the process or rent out proprietary equipment to others. | The LIFTEX Process is so safe and secure that it is performed even in occupied warehouses, without disrupting ongoing operations, and without needing to vacate the roof-raise area. |

Structural engineering

Complete structural engineering is provided by licensed professional engineers. The included stamped drawings show compliance with building codes, including provisions for seismic, snow load, and wind shear considerations where applicable.

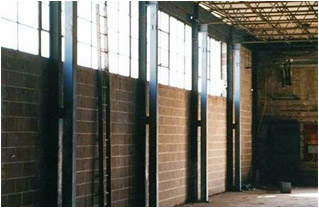

Wrap vertical columns with support “Sleeves”

Interior vertical columns are enclosed within steel “sleeves” that allow the original columns to rise as they lift the roof. The sleeves remain in place to provide new and stronger lower support.

Attach “Lifting Columns” to perimeter columns

Perimeter columns are fitted with additional telescoping “lifting columns” that raise the roof perimeter and remain as integral parts of the lifted, strengthened structure.

Install lifting equipment; Separate walls from roof

Proprietary LIFTEX collars, clamps, and hydraulic lifting mechanisms are installed at each prepared column. This system avoids the need for temporary shoring and the resulting floor damage. The building is never separated from its foundation and is never subjected to instability.

Install temporary utility extensions

Local contractors disconnect sprinkler riser, and install temporary extensions of lighting, power, HVAC, and drainage lines, allowing these utilities to remain uninterrupted during lifting.

Actuate lifting equipment

Lifting equipment is activated, adding one foot of additional roof height every hour, in a precise and even interval, preserving roof condition and pitch.

Install insulated steel paneling (optional)

Insulated steel paneling is installed to enclose the newly created height, if requested. This wall system provides an attractive exterior finish and a light-reflective interior surface. The paneling provides long-term durability and energy-saving thermal insulation.

© Raise the Roof Logistics

All Rights Reserved

All Rights Reserved